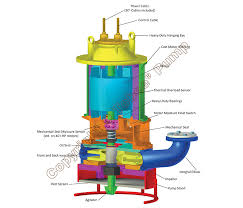

1. The Submersible Slurry Pump is a single-stage suction type with a stirring impeller at the bottom. It is integrated with the motor in the water. Thus, the settled sludge can be stirred and pumped away as much as possible.

2. The wet end of the Submersible Slurry Pump is made of wear resistant alloy for high wear resistance. It has a wide wet channel and can handle slurries with larger solids.

3. Submersible Slurry Pump is manufactured on the basis of absorbing advanced technology at home and abroad. The submersible motor is equipped with leakage, overheating and moisture protection to ensure trouble-free operation in harsh conditions.

4. High-quality cable seals ensure protection against water leakage

5. Heavy-duty bearings for shock and overload

6. Reinforced Dual Silicon Carbide Mechanical Seals for Loaded Applications

7. Unique aluminum alloy provides the perfect combination of strength, light weight and corrosion resistance

8. High chrome impeller provides higher wear resistance

9. Wide base ensures stability while allowing passage of large solids

Want more details? Feel free to contact us any time! We will give you the most professional answer in the shortest possible time!

Mines, quarries, coal ore and slurries

Sewage treatment plant

General pumping use

Pumping fluids: sludge, slurries with liquid and bentonite

Size

The size of the Submersible Slurry Pump is important when connecting the discharge end. The hose or pipe connecting the pump should match the discharge port or pump. Typically, the size of the pump limits the amount the Submersible Slurry Pump can pump per minute. The larger the pump size, the larger the allowable volume and solid size.Strength

The power of the Submersible Slurry Pump depends on the horsepower of the motor. The more horsepower, the more material (volume) it can move and the higher head it can pump. When moving sand and mud, it's important to consider horsepower.

Volume

When choosing a Submersible Slurry Pump, be sure to understand the volume of material you are moving. Ensuring the correct power to the Submersible Slurry Pump is critical to delivering the sand the desired distance, as the sand is heavy and will settle. Not having enough power will leave sand in the hose. Solving liquid viscosity is also important to ensure successful pumping.In addition to the amount of material you are pumping, you also need to ensure that there is a consistent inflow of water or fluid in place of the liquid and material being pumped out for proper operation. For the Submersible Slurry Pump, a lack of fluid is bound to affect normal operation.

Name: KATImachinery

Mobile:+86031180632344

Tel:+86031180632344

Email:info@katimachinery.com

Add:306-1 Zhongchuang building 5,No.251 Yucai street, Shijiazhuang China